Vibration & Thermography Monitoring

Vision

The Vision of Vibration and Thermography Consultancy at KLS, Vishwanathrao Deshpande Institute of Technology, Haliyal with Diagnostic Engineers, Bangalore is to make students Industry Ready, corporate training for Industries / Faculties and Consultancy for Industries in the area of Vibration and Thermography. The consultancy will be Mentored / Guided under the leadership of Mr. Madhusudan N, Vibration Analyst, CAT–II, ISO Certified, Diagnostic Engineers, Bangalore. He has got rich experience in the area of Condition Monitoring for more than 21 years covering various sectors like Power sector, Steel Sector, Petroleum Oil / Refineries & Automotive Sector. The KLS VDIT will be the first college to start Proficiency Center with Industry Connect in North Karnataka & North Kannada.

Why Vibration Monitoring and Thermography ?

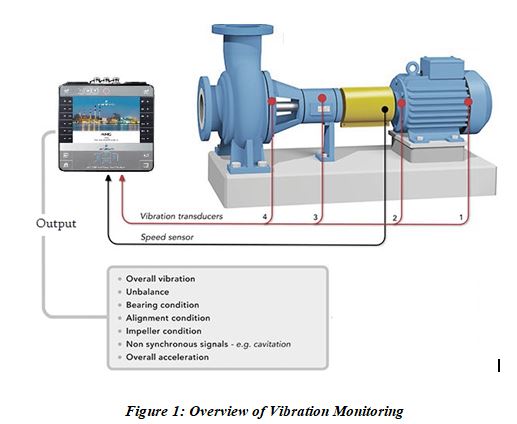

Vibration monitoring is process of noticing a change in displacement/velocity/acceleration in rotating machine. Using FFT analyzer, the signals are collected in three different directions i.e. horizontal, vertical & axial directions. The centrifugal forces are increased at faulty location thus seen increase in amplitude at certain frequency. The overview of vibration monitoring is shown in figure 1,

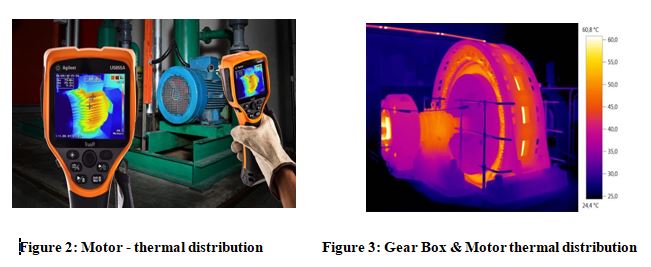

Thermography is an excellent condition monitoring tool to assist in reduction of maintenance costs of the system. This technique allows for the monitoring of temperatures and thermal patterns while the equipment is online and running under full load. Most mechanical equipment has allowable operating temperature limits that can be used as guidelines. Infrared Thermal Imaging can be used on a wide variety of equipment including pumps, motors, bearings, pulleys, fans, drives, conveyors etc. Infrared Thermal Imaging enhances a company’s ability to predict equipment failure and plan corrective action before a costly shutdown or equipment damage.

Instruments for Vibration & Thermography Monitoring

Instrument

Specifications

Snapshot

Emerson CSI 2140

- Frequency Range: Dc to 10 Hz minimum, DC to 80 kHz maximum

- Dimensions (h x l x w): 248 mm x 40 mm x 226 mm

- Weight: 1.79 kg (3.95 lbs)

- Operating Temperature: -10 to 50°C (14 to 122°F)

- Long-term Storage Temperature: -20 to 35°C (-4 to 95°F) with battery.

Thermal Imager, Fluke Ti-400

- Image capture frequency: 9Hz

- Temperature measurement range: -200C to 12000C

- Temperature measurement accuracy : ±20C

- Infrared spectra hand : 5µm to 14 µm (long wave)

- Minimum focus distance: 15cm

Laser displacement sensor

- Make: Panasonic

- Measurement center distance: 50mm

- Measurement range: 10mm

- Resolution: 5micrometer

- Supply voltage: 24V DC

Why Our Services?

Because we have mentor of 21 years of experience in,

- Vibration Data collection, Data interpretation, diagnosis and trending of rotating machines.

- Hands on experience on usage of vibration data collectors for Vibration Monitoring of mechanical equipments.

- Rotating machines on-site balancing.

- Trouble shooting of rotating machines(misalignment,looseness,bent shaft etc)

- Natural frequency measurements of turbine blades.

- Sound spectrum analysis.

- Thermal Analysis.

Responsibilities Performed Till Date

- Schedule based Vibration Monitoring of Rotating equipment’s (Annual maintenance contract) for auto, oil refineries paper mills, pharmacy and process industries.

- Vibration analysis and on-site balancing of turbine-gearbox-generator assembly at power plants.

- Handled several TG sets starting from 2 MW to 150 MW sets.

- Vibration studies and on-site balancing of paint shop blowers, fans, stand-alone generator assembly, motor assembly, Horizontal machining centre, vertical machining centre.

- Hands on experience in Analysis like Equipment’s Unbalance, Misalignment, Mechanical Looseness, Bearing failures, Blade pass-Vane pass, Gears & Belt related problems.

- Bump tests performed on rotating machinery components like couplings, turbine blades, pulleys etc to know the resonance band/critical speeds.

Major Assignments Handled Till Date

- Vibration studies and diagnosis of 2X25 MW gas turbine power plant at BAFA, Bahrain.

- Vibration measurements and on-site balancing of high speed spindles which runs at 30000 rpm.

- Blade natural frequency tests for 150, 230 MW turbines at National Thermal Power Corporation India.

- Shaft failure analysis and investigation for HCL technologies.

- Handled several vibration studies and on-site balancing assignments for Toyodenki power systems (In Collaboration with Toyodenki Japan) high capacity generators starting from 8 to 35 MW sets.

- On-site balancing of 54 ton generator rotor-motor assembly at Central Power Research Institute, Bangalore, India.

- Vibration measurements and trouble shooting of 30 MW Gas Turbine Gearbox-compressor train, Doha offshore at one of the leading Petroleum refinery in Qatar.

- Vibration studies and analysis of 2 X 2.5 MW Hydro machines for Boving Fouress at Srilanka &Vibration studies and on-site balancing of 60 MW Hydro generator at Sabarigiri power station, India (First of its kind high capacity hydro station in India).

- Rotor dynamic support for handling vibration problems in a 35 MW TG set at one of the sugar mills (Software used: XL Rotor).

- Failure investigation and reporting of a Demag compressor blades at Tata Steels, Jemshedpur, India

- Vibration studies and on-site balancing of motor-generator-flywheel assembly. Weight of the flywheel was 16 tons and runs at 1500/1800 rpm. This machine was first of its kind developed in India for short circuit testing and analysis.

- Corporate training on vibration basics and condition monitoring at Caledonian College of Engineering, Oman.

Our Customers

Our Team

Mr.Madhusudan N,

(Mentor/Guide),

Vibration Analyst, ISO CAT II,

Diagnostic Engineers, Bangalore.

Dr. V.A. Kulkarni

Principal

KLS VDIT, Haliyal

Dr. K. S. Pujar

Professor, Mechanical Engineering, KLS VDIT, Haliyal

Dr. Murgayya S Basavanakattimath (Vibration Monitoring), KLS VDIT, Haliyal.

Mr. R J Talapati (Thermography), KLS VDIT, Haliyal.

Dr. S N Badiger (Thermography), KLS VDIT, Haliyal.

Contact Us..!

9845428909 / 9900920986

ics@klsvdit.edu.in